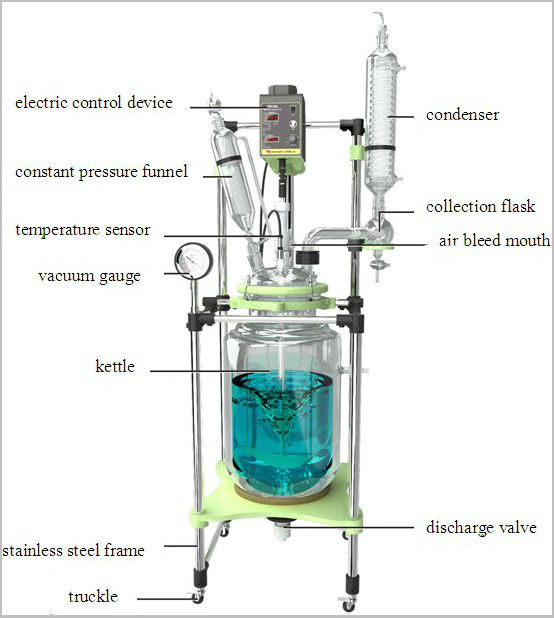

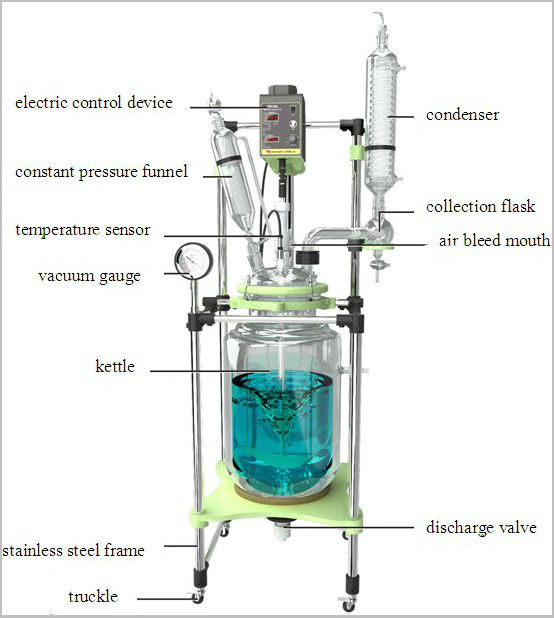

Heat Transfer Fluid Heated 30L Glass Reactor GR-30L

Brief Introduction of GR-30L:

Reagents are set in the inner layer of double-layer glass reaction kettle, at the same time, vacuum can be taken out and mixing speed be adjusted. Interlayer can lead in refrigerating fluid, water and high temperature liquid to heat and cool the materials.

Application of GR-30L:

1.It can be used in the experiment, middle-scale test, and production of chemistry, fine chemical engineering, biological pharmacy and synthesis of new materials.

2. Can be matched with water circulating multi-use vacuum pump and circulating bath ( including high temperature circulating water/ oil bath; and high/low temperature hermetic refrigerated and heating circulator ) to form the total systems as follows:

Circulating Water Jet Flow Vacuum Pump SHB-B95A + Glass Reactor GR-30L + Minus 80~200 Celsius Hermetic Refrigerated and Heating Circulator ZT-50-200-80

Teflon Circulating Water Jet Flow Vacuum Pump SHB-B95T + Glass Reactor GR-30L + 99 Celsius Circulating Water Bath SY-X1-30L

Common Circulating Water Jet Flow Vacuum Pump SHB-B95/ SHB-B95A + Glass Reactor GR-30L + 250 Celsius Hermetic Circulating Oil Bath SY-30-250

Technical Data of GR-30L:

|

Product

|

30L Two-layer Borosilicate Glass Reactor

|

|

Model

|

Two-layer GR-30

|

|

Effective volume inside glass reactor (L)

|

30

|

|

Jacket capacity(L)

|

10

|

|

Heat transfer area of jacket(m²)

|

0.46

|

|

Heat transfer area of condenser(m²)

|

0.3

|

|

Material of glass reactor

|

High borosilicate glass 3.3

|

|

Material of fixed frame and connecting parts

|

Stainless steel 304

|

|

Temperature range of kettle(°C)

|

-80~200

|

|

Operating pressure(Mpa)

|

Vacuum or constant pressure

|

|

motor

|

Power(W)

|

90

|

|

Adjusting mode

|

Variable frequency speed control

|

|

Rotary speed (rpm)

|

50~500

|

|

Six opening of glass reactor cover

|

Mixing open mouth

|

¢50mm Flange opening

|

|

Opening of temperature sensor

|

24# standard ground joint

|

|

Connecting opening of condenser

|

50# standard ball joint

|

|

Liquid-adding opening

|

34# standard ground joint

|

|

Constant pressure funnel connecting opening

|

34# standard ground joint

|

|

Solid-adding opening

|

¢80mm Flange opening

|

|

Liquid-circulating inlet and outlet of kettle

|

DN15

|

|

Material of sealing parts

|

PTFE

|

|

Power supply

|

220V 50HZ

|

|

Discharge valve

|

Open-type of discharge, PTFE material, effective distance from discharge valve to ground: over 400mm

|

|

Material of temperature sensor

|

Stainless steel covered with fluorine outside, double anti-corrosion

|

|

Stirring

|

Rotary vane agitator, stainless steel axis covered with PTFE outside

|

|

Volume of constant pressure funnel(L)

|

2

|

|

size (mm)

|

External diameter:¢13.5mm; Internal diameter:¢8mm

|

|

Dimension(mm)

|

660L×535W×2020H

|

Detail Pictures of GR-30L:

Vacuum Meter

Vacuum material-adding opening

Lid of Reactor

Discharge Valve

Features of GR-30L:

1. High borosilicate glass 3.3 has good physical and chemical properties.

2. Can be used in wide temperature range from high temperature (200°C)to low temperature(-80°C).

3. Can work in constant pressure and vacuum, vacuum degree is below 0.095MPa in quiet situation.

4. Digital display of mixing speed, , frequency conversion, and constant speed mixing system, work steadily.

5. Long service life PTFE vacuum seal.

6. Corrosion resistant discharge valve is without dead space design.

7. The cooling or heating solution in the interlayer can be completely removed after reaction.

8. The whole structure is novelty, practical and beautiful.

9. We manufacture 5L ~ 100L single-layer/ two-layer ( explosion-proof ) borosilicate glass reactors optional, and 5L ~ 50L three-layer ( explosion-proof ) borosilicate glass reactors optional.

Our Advantages:

a). Customized Service is offered according the special requirements

b). Prossional technicists guarantee exellent after-sales service

Glass Reactor Workshop:

bio-equip.cn