There are two kinds of decanter centrifuge.2 Phase and 3 phase decanter centrifuge:

2 Phase Decanter Centrifuge

The two-phase centrifuge can realize the separation of two immiscible liquids and liquid and solid. The entire separation process is continuous and automatic without human operation. Two-phase centrifuges are widely used in many fields such as environmental protection, sewage treatment, chemical industry, steel, food, fermentation, metal, and non-metal mineral mining.

The decanter centrifuge's hour has come as soon as the solids content in the suspension to be processed is particularly high. These decanter centrifuges provide the benefits of high clarifying efficiency and maximum dewatering as well as the separation of liquids with the simultaneous removal of solids. The main requirements in this respect include a high bowl speed, a powerful drive for the scroll and a scroll speed which automatically adapts to the solids loading in the feed. Due to its versatility and the technological know-how of Huading Separator, the decanter centrifuge can be used for a wide range of process tasks; from clarification through separation, classification, concentration and washing right up to extraction.

Decanter centrifuge designs:

Decanter centrifuge designs:

Clarifying decanter centrifuge for clarifying liquids

Dewatering decanter centrifuge for maximum concentration of solids

Concentrating decanter centrifuge for the concentration of solids

Separating decanter centrifuge for the separation of liquid mixtures and the simultaneous separation of solids

Classifying decanter centrifuge for the extraction of different solid fractions

Extraction decanter centrifuge for the extraction of reusable materials

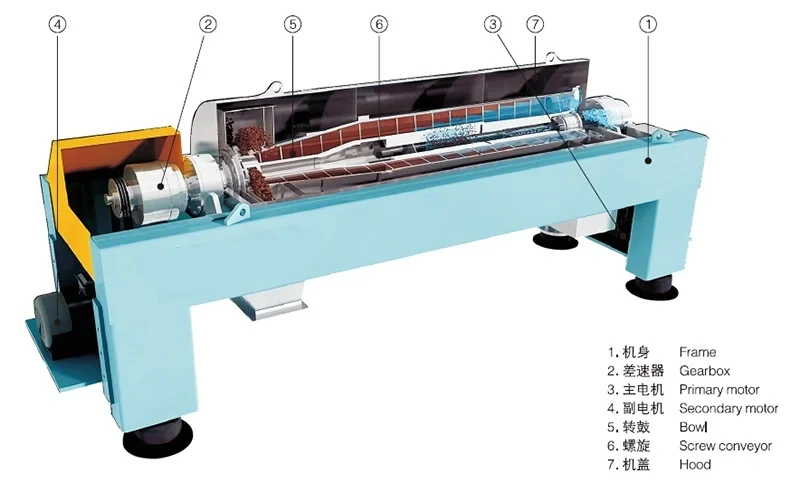

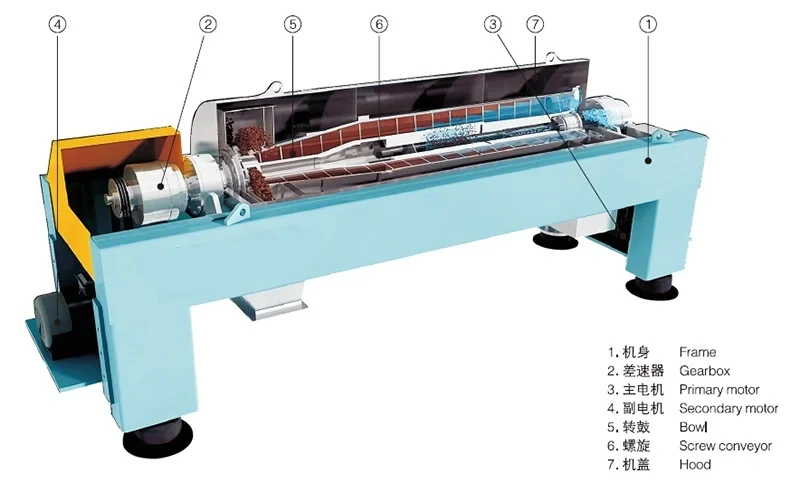

MAIN COMPONENTS

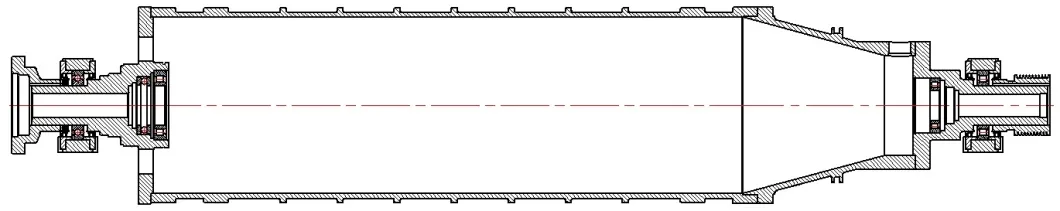

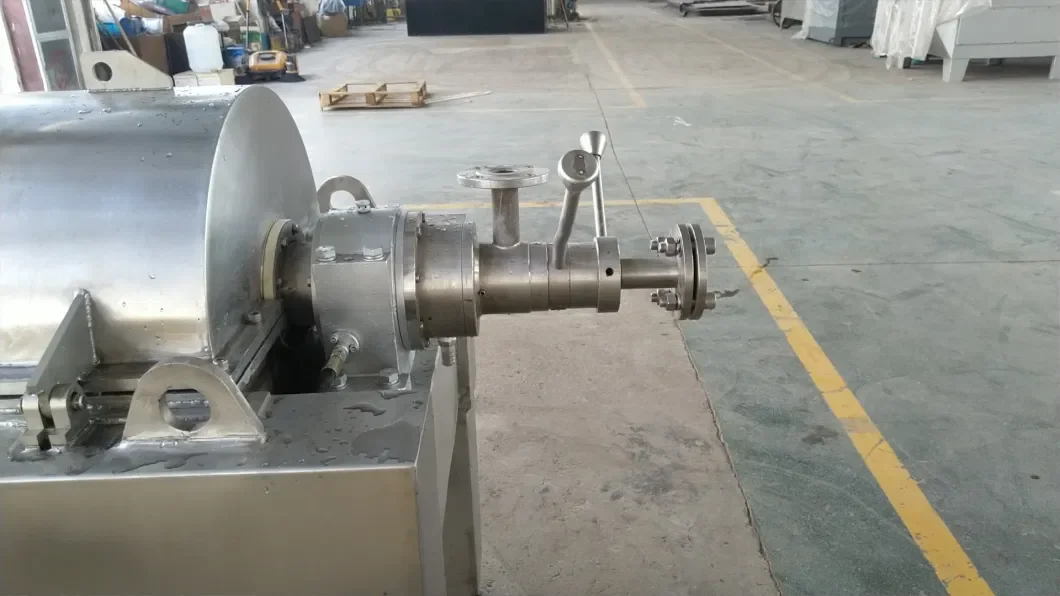

The decanter centrifuge is mainly consists of the bowl, the screw conveyor, the gearbox, the frame with the hood, the feeding, and the discharge arrangement.

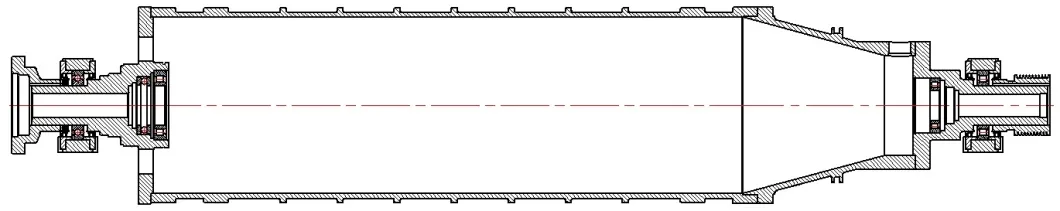

BOWL

The bowl in a modern decanter is a cylindrical tube with a flange at either end, on which are bolted at one end the liquid discharge bowl hub. and, on the other end. the cake discharge hub, or the beach followed by the cake discharge hub. The first cylindrical bowls used a filler piece in the end of the bowl to form the beach. On modern bowls. particularly the larger ones, the beach is bolted to a flange at one end of the cylindrical section. although with some overlap to provide mechanical location.

The thickness of the bowl wall is dictated by the material of construction used, the maximum speed at which the bowl will be rotated. and the maximum weight of process material. feed, centrate or cake, likely to be held in the bowl. Thus the density of the process materials in use can have a major effect on the safe working speed of the bowl.

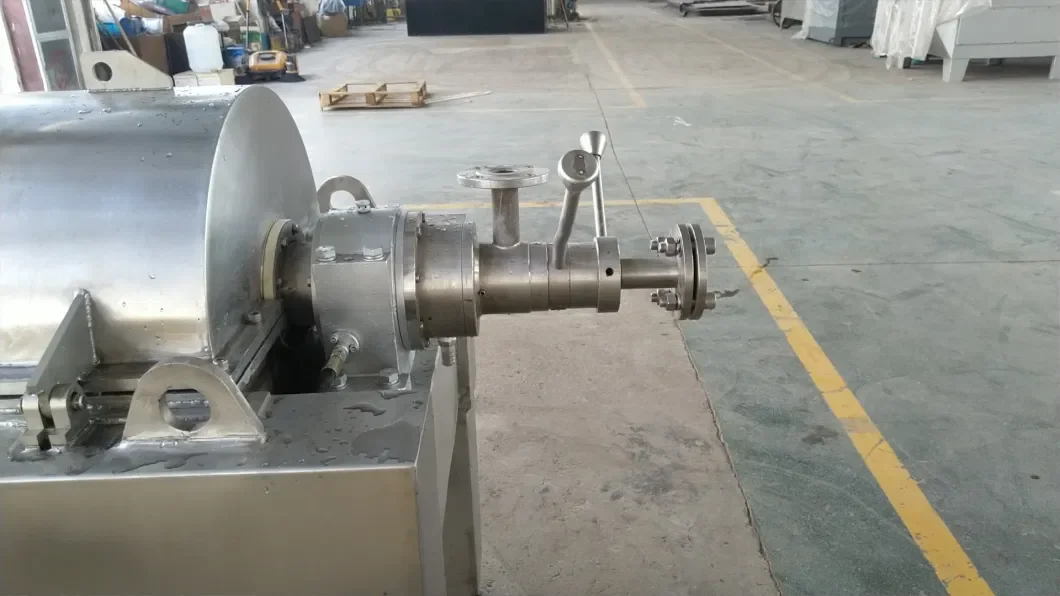

SCREW CONVEYOR

The screw conveyor (or scroll) is in the form of an Archimetlian screw. fitting inside the beach and bowl between the two end huhs. with a small clearance of less than 2 mm ratlially. lt has a number of functions. Not only does it convey the solids, after they form a cake. along the cylindrical bowl section and up the beach, it also accepts the feed and accelerates it up to bowl speed.

In its simplest form, the conveyor has a cylintlrical central hub with a set of flights welded onto it, to form one contirluou ,helix. The conveyor bearings and associated seals are housed in both ends of its central hub. Somewhere in between the bearings will be a chamber called the feed zone, sealed and isolated from both bearings.

GEARBOX

The gearbox is a major component of the rotating assembly, which creates the differential speed between the bowl and the conveyor. Usually, the screw conveyor driven by a planetary gearbox turns slightly slower than the bowl.

There are two main types of gearboxes used on decanters. These are the epicyclic gearbox and the Cyclo gearbox.

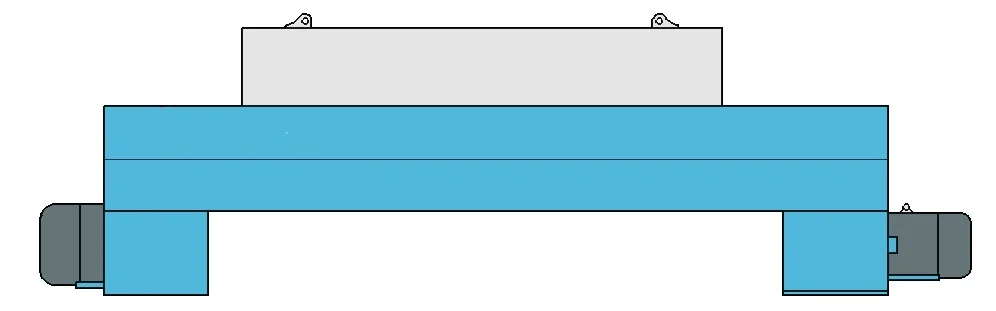

FRAME AND HOOD

Usually, the frame is fabricated from steel channel or box sections. The frame needs to be a rigid support for the rotating assembly. The surfaces for the main bearing pillow blocks are accurately machined in the same plane, and in line. to ensure no end-to-end misalignment of the rotating assembly. which would cause premature bearing failure.

The frame and hood act as the link between the high g field of the rotating assembly and the stationary area around it.

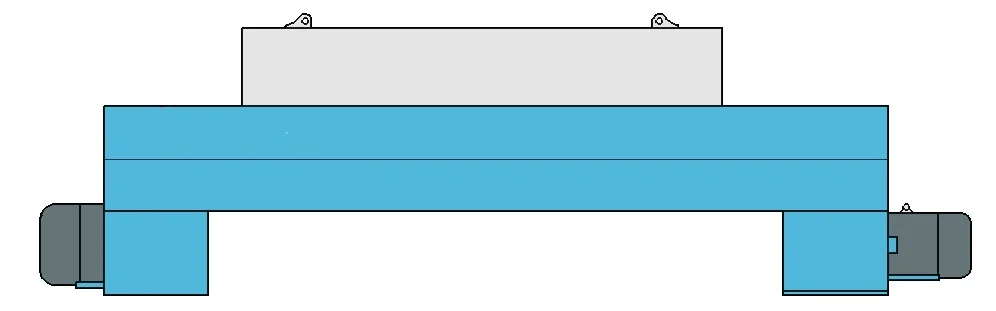

3 phase decanter centrifuge is mainly designed for Solid-liquid-liquid three-phase separation of materials.With our over 30 years of experience in the separation industry, it is the most advanced type machine for 3 phase separation. It is designed for 24 hours continuous and smooth operation throughout the day. It is mainly composed of driving system, decanter bowl, screw conveyor inside the bowl, cover box, skid and VFD control panel.

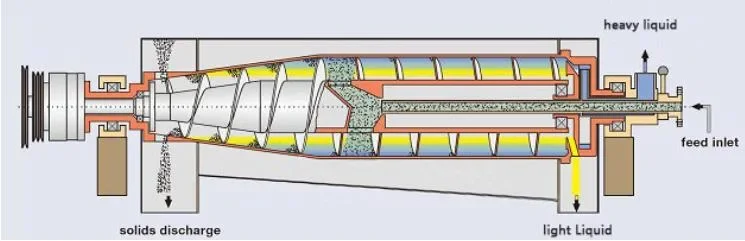

To ensure that the separation process can take place, the solid phase must be the specifically heaviest phase and the two liquid phases must have different densities.The main difference between the 2 phase decanter and 3 phase decanter is that the 3 phase decanter not only separate the solids but also separate two phase of the liquid.

3 phase decanter is widely used for oil , water, solids separation industry.

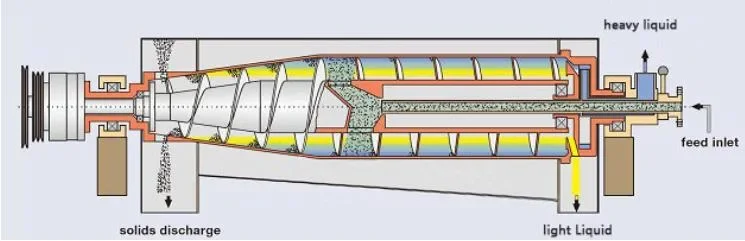

3 PHASE DECANTER WORKING PRINCIPLE

The three-phase decanter centrifuge operation is based on the principle of sedimentation, that is, solid particles with specific liquid weight precipitate in a predetermined time. This principle can also be applied to two immiscible liquids with different specific gravity. When the material enters the high-speed rotating drum, the material rotates synchronously with the drum. Because of the different specific gravity, the centrifugal force is different. The solid particles with the larger specific gravity are subjected to the greatest centrifugal force, followed by the heavy phase liquid (such as water) and the light phase liquid (such as oil). So the centrifugal force is becoming less from outside to inside according to the magnitude of centrifugal force. A concentric solid layer and two liquid layers are formed. Solids are pushed out by the screw conveyor, and liquids are removed from their respective nozzles. Therefore, the application of three-phase decanter centrifuge can not onlyseparate the solid in the material, but also separate the two-phase liquid with different specific gravity in the material, that is, Solid-liquid-liquid separation can be achieved.

BOWL ASSEMBLY FEATURES:

- Bowl Material: Duplex Stainless Steel SS2205

- Solids Discharge port: Tungsten Carbide insert

- Bearing: NSK Brand

- Gearbox type: planetary wheel type

- Screw Conveyor Material: Duplex Stainless Steel SS2205

- Material Distribution Nozzle: : Tungsten Carbide insert

- Screw Conveyor Wear Protection: Tungsten Carbide Tiles

- Differential Speed: Adjustable according to conditions

- Bearing: SKF or Japan NSK Brand

-

3 PHASE DECANTER ADJUSTABLE SEPARATION

Flexible for different Liquid Phase Proportion

An adjustable impeller discharges the "heavy" liquid phase. Furthermore, the operator can use the adjustable impeller to adjust the pond depth of the heavy liquid without difficulty during ongoing operation. According to the Proportion of two different phase, An adjustment mechanism causes the position of the impeller to change, thus changing the separation line of the liquids. The process engineering results can thus be influenced so as to achieve the required separation result.

-

If you want to know more please contact me:Cathy Tel:+8613130722088(WhatsApp)

bio-equip.cn

Decanter centrifuge designs:

Decanter centrifuge designs: