1. Continuous working, spiral discharging, high capacity.

2. Compact structure and easy maintenance.

3. Wide applicability for chemical, oil, foodstuff, chemical industries and green industry in which solid-liquid separation is

required.

4. Suitable for various products, capable for separating wide-ranging solid phase grains( 0.005 - 2mm ), especially when separating solid phase has different size grains.

Application:

Decanter centrifuge is widely used in industries as municipal and industrial waste water treatment, food processing,

and chemicals, etc.

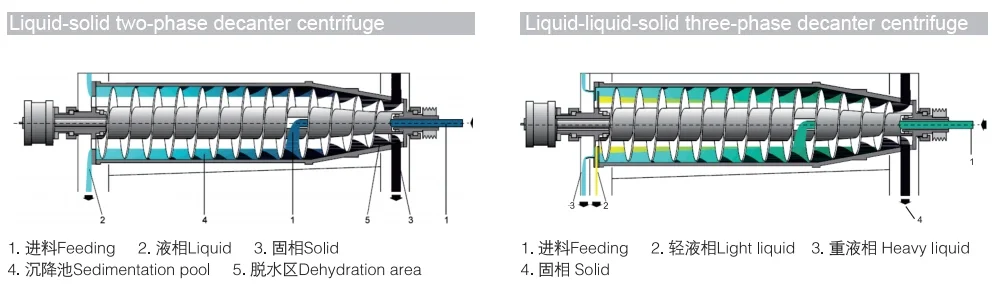

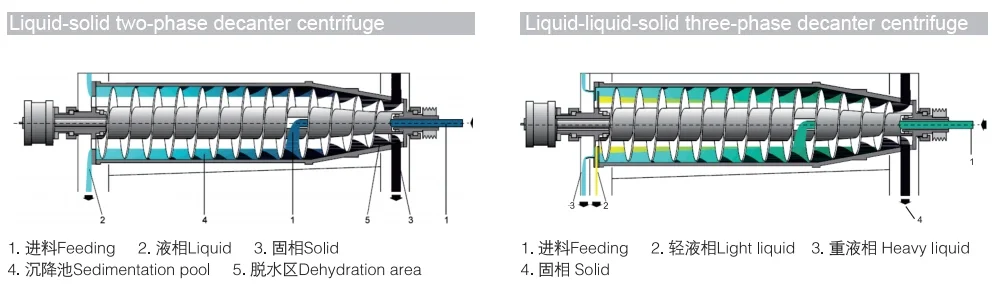

1. Decanter centrifuge solid phase dehydration: dehydration effect for processing materials of solid particles.

2. Decanter centrifuge particle size classification: used in the removal of material of large diameter solid particles.

3. Decanter centrifuge liquid clarification: used for removing solid particles in the suspension liquid are clarified

Details