Olive Oil Cold Extraction Line

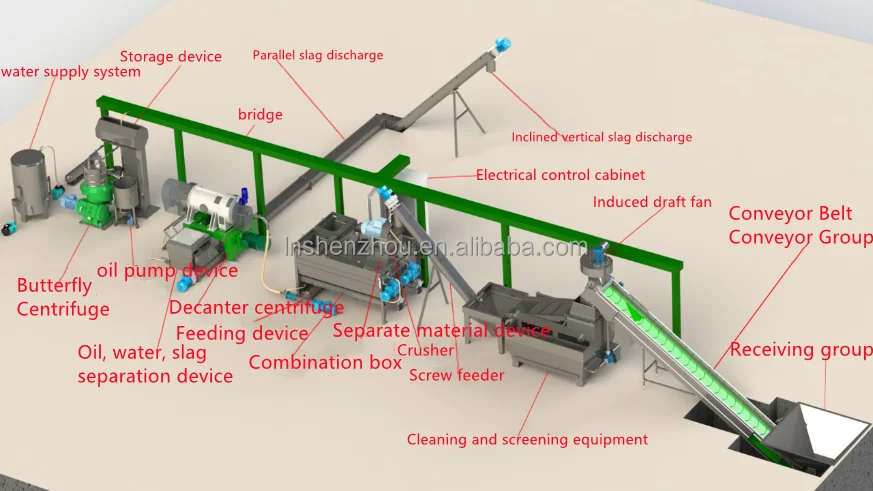

CENTRIFUGE EXTRACTION LINE is designed specially for EXTRA VIRGIN OLIVE OIL extraction from the ready paste by 2-phase or 3-phase separation(which is followed as per local government rules regarding the pollution issues).

Cold pressed extraction process could replace the traditional solvent extraction method to produce a virgin olive oil for the edible oil market.

Generally,the whole system consists of the following 6 steps

1.- olive fruits reception and leaf removal system

2.- olive fruits washing system

3.- olive fruits crushing and paste malaxing system

4.- olive oil extraction system (2/3 phase optional)

5.- olive oil purification system

6.- olive oil storage and bottling system

All components such as decanter centrifuge and vertical separator are made in china!