- Hygienic design: All parts that come into contact with the product are made from corrosion-resistant stainless steel. This means we meet all hygiene requirements and guarantee the highest standards

- Adjustable impeller for optimum setting of the product feed - even with fluctuating feed quantities

- ISO certification: Shenzhou is certified to ISO 9001 and builds its products according to the latest technical standards

- Made in China - centrifuges are exclusively manufactured in China by specialist technicians

- Many years of experience and in-depth technical knowledge of separation technology, the oil industry and centrifuge production

- Personal support, on-site service and individually tailored project planning mean we meet your requirements

3 Phase Automatic Decanter Centrifuge For Avocado Oil Extraction Machine manufacturing plant

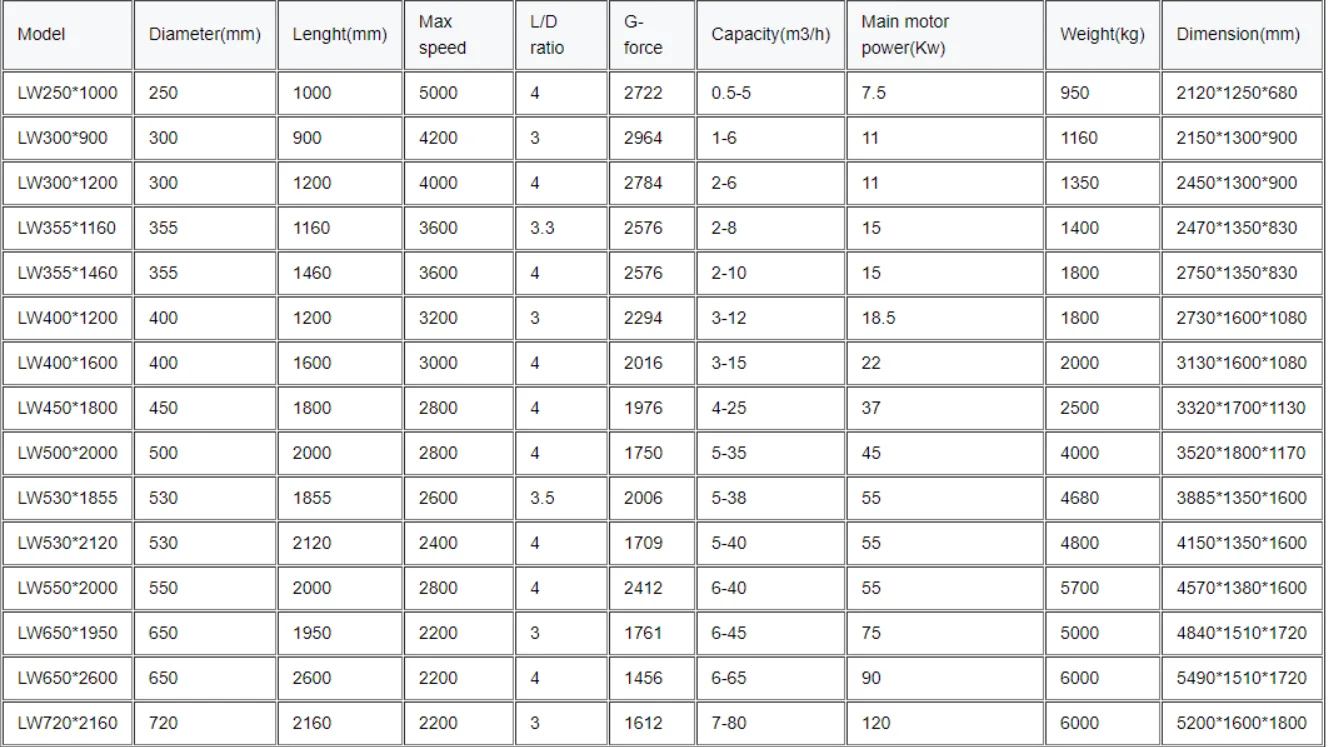

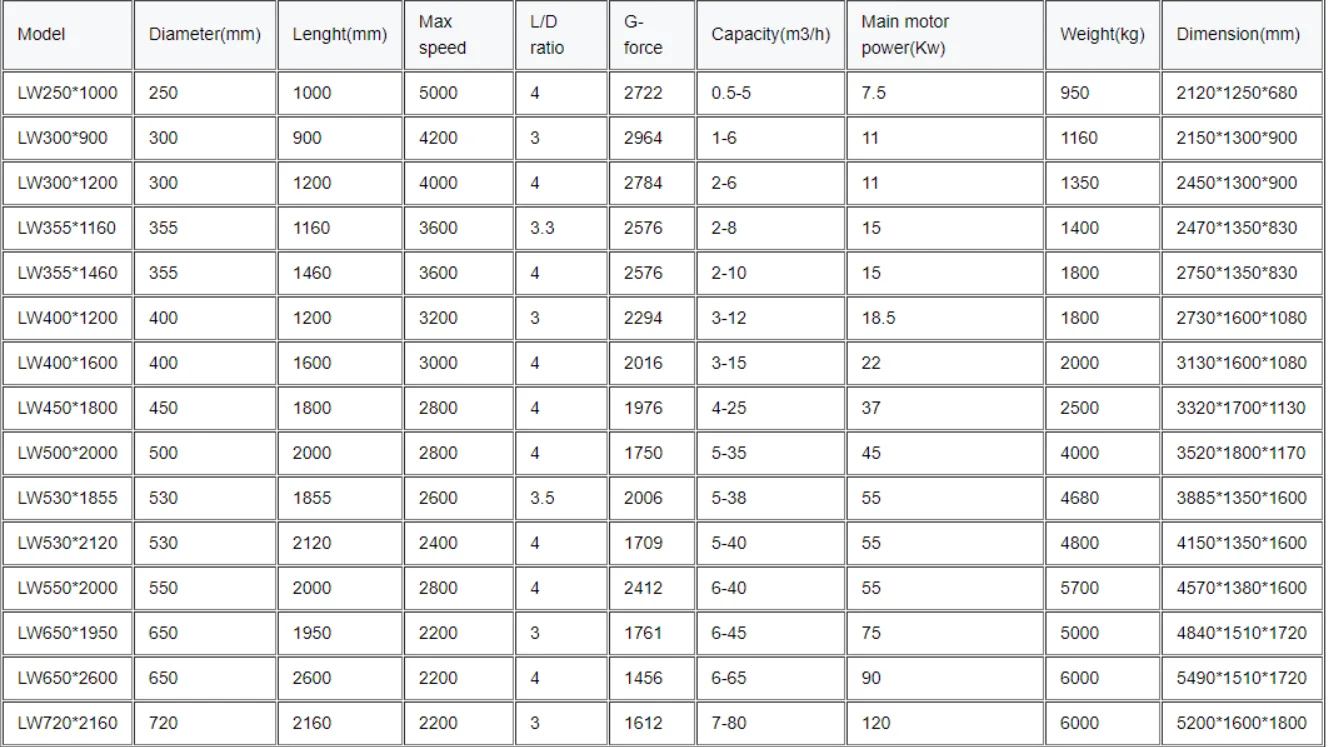

Three phase decanter centrifuge is used to separate two liquid phases from one solid phase at the same time. As is known, decant centrifuge principle of separation is by G force. Because of the different densities of the (immiscible) liquids and the solid , so all three phases can be discharged simultaneously using the 3 Phase decanter centrifuge. Shenzhou design and manufacture three phase decanter in different bowl size

However, to do the 3 phase separation, the solid phase must be the specifically heaviest phase and the two liquid phases should have different densities.

The structure and principle of the three phase decanter centrifuge are similar to the two phase decanter centrifuge. The

difference is the way of the liquid discharged. There are two liquid phases in separation in a 3 phase decanter centrifuge. A higher density liquid phase is discharged under pressure, and the lower density liquid is discharged without pressure. Following is the principle drawing of the 3 phase decanter centrifuge.

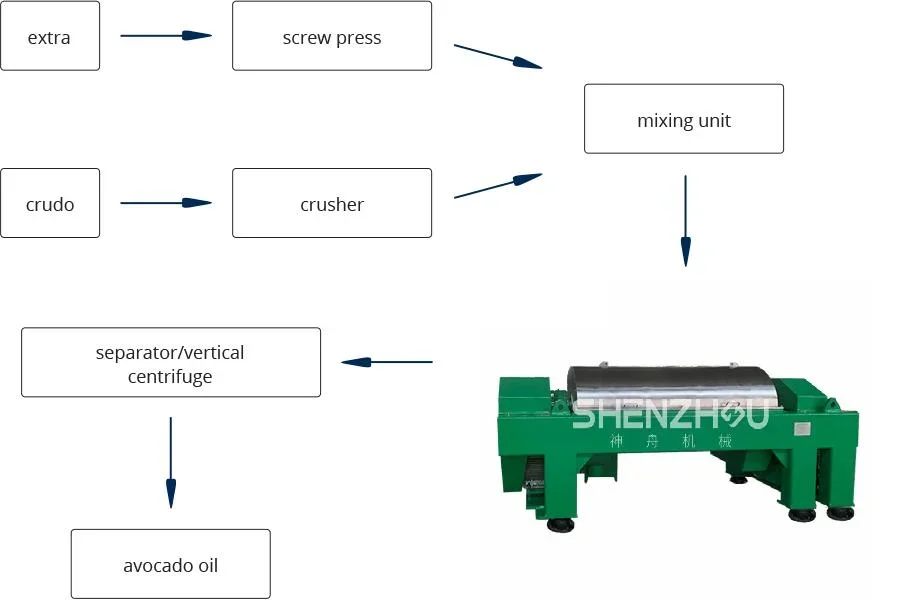

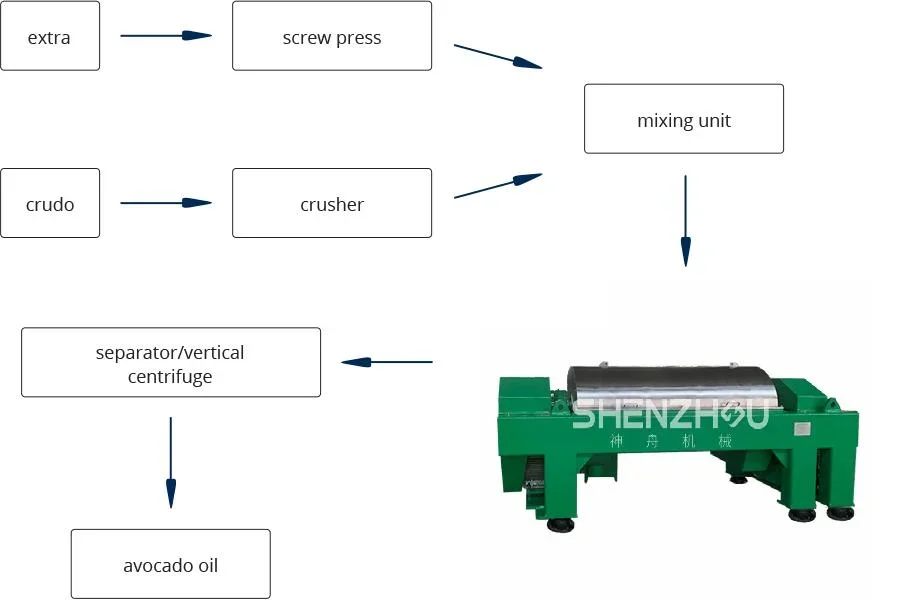

How to extract an excellentAvocadooil:

How to extract an excellentAvocadooil:

1.Raw material:The fresh fruit after harvest takes about a week to mature,After the fruit is ripe, it is processed again.

2.Washing : Cleaning up dust, sediment, and a large number of microorganisms and residues of chemical pesticides on the surface of fruits and vegetables,Ensure product cleanliness and hygiene.Rinse fruits and vegetables again in the ascending section with clear water , to eliminate the effects of microorganisms in residual tap water on fruits and vegetables . .

3.De-stoning and partial peeling :remove pericarp ,kernels and other impurities,To get a clean pulp.

4.Crushing :Fine grind the pulp so that the cells in the pulp are fully broken,To facilitate the separation of avocado oil.The quality of fine grinding directly determines the oil yield.

5.Malaxing:Dilute the crushed pulp,Dilute to a pulp containing 15% pulp,Adding anti-emulsifier in a certain proportion during dilution,And set the acid value PH value to 5.55.6.Prevent oil from emulsifying in slurry, To ensure the oil yield,After dilution, steam can be used to heat it,Boil for 5-10 minutes,Further free the avocado oil from the pulp.

6.Separation:The heated pulp is still a three-phase mixture of oil, water and slag,To separate avocado oil from it, you also need to send the pulp to a centrifuge for centrifugation,Note that the temperature of pulp should be kept between 80 C and 90 C during centrifugal separation,Avocado oil with high purity can be obtained by centrifugation.

Plant Benefits:

1.Avocado oil lines for batch and continuous processing

2.Design concepts for different capacities

3.Adjustment of machine parameters according to changes in product and process conditions

4.Simple control and handling Robust, sturdy quality "Made in China"

5.High efficiency - fast pay back time

6.Maximum product yield and minimum residual oil content in the pomace through innovative centrifugal technology

7.Low fresh water consumption with minimum waste water reduces environmental pollution

8.No manual cleaning of the disc stack thanks to the self-cleaning bowl of the separator

9.Polishing separator for minimum oil losses during discharge and automatic disc cleaning

10.Minimum oil oxidation thanks to centripetal pump 1-2% more oil yield than comparable machines

11.No additional separator needed for waste water because of adjustable paring tube Improved malaxer for high quality olive oil

12.Customer proximity and on-site service due to world-wide sales and service network In-depth know-how: more than 50 years of experience in the development and design of centrifuges.