Under full speed operation: continuous feeding, washing, dewatering, unloading and other technological operations of the

suspension.

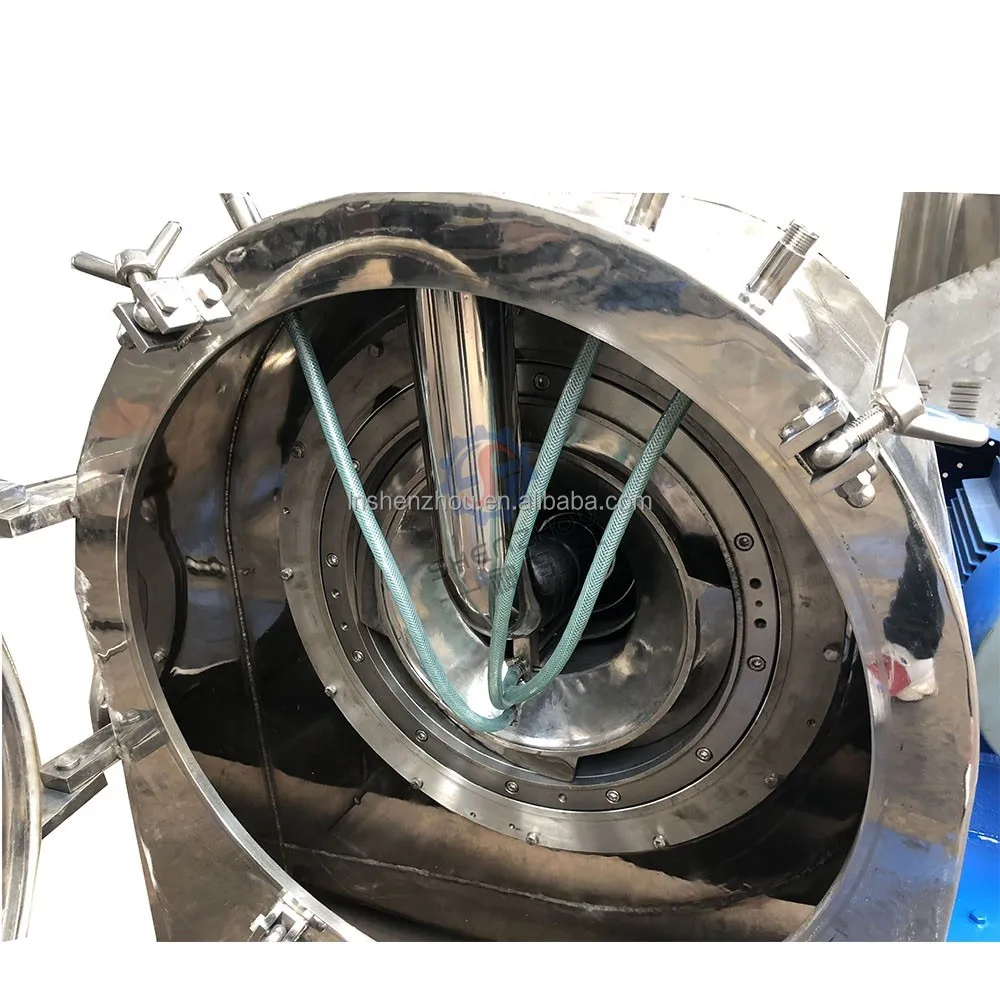

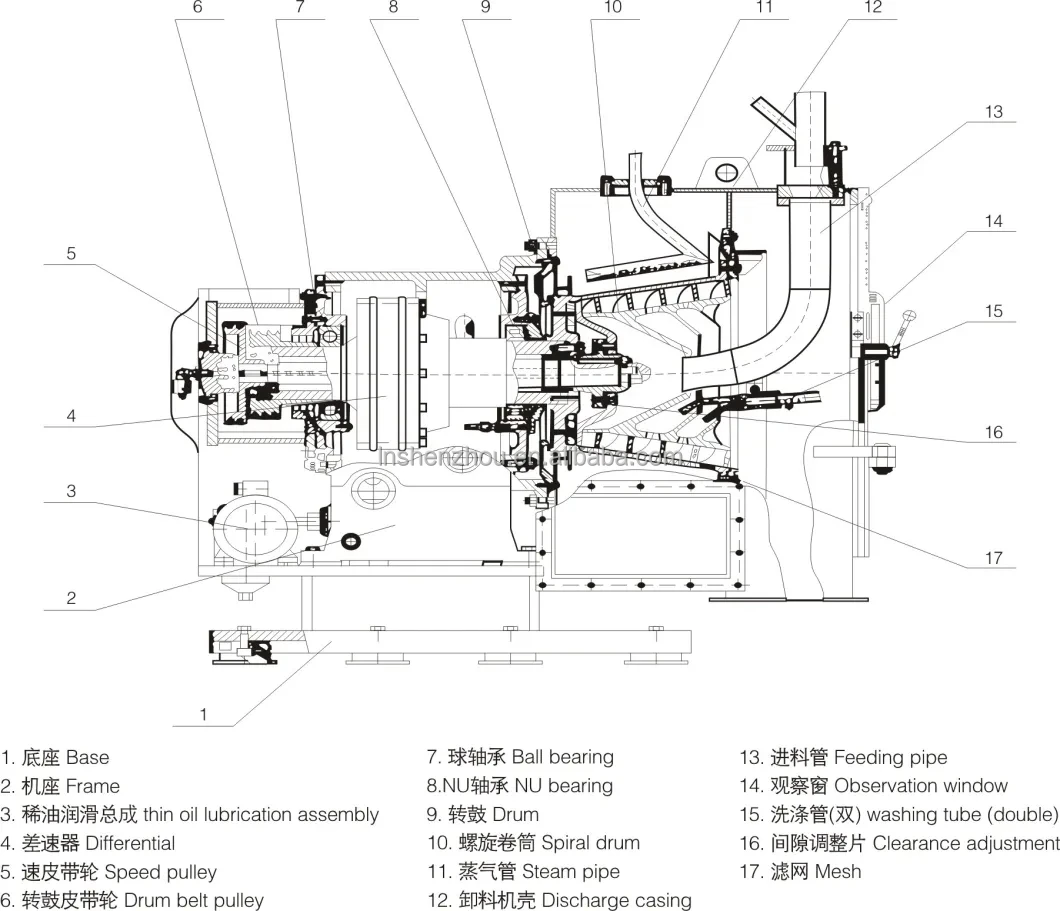

The suspension enters the spiral cavity from the feed pipe and enters the drum through the nozzle at the bottom of the screw head near the bottom of the cone.

Under the action of the centrifugal force field, the liquid phase in the slurry is separated by the screen set on the rotating

wall When going out, the solid particles are trapped in the drum; at the same time, the solid particles in the drum move from the small end of the drum to the big end of the drum under the action of centrifugal force and the differential speed between the spiral and the drum.

During the movement, the centrifugal force increases rapidly due to the increase of the rotation diameter. The solid phase changes from the high moisture content solid phase when it initially enters to the low moisture content solid phase when it is discharged from the drum, thus realizing automatic and continuous solid and liquid phase separation.

The suspension enters the front end of the spiral from the feed pipe and is initially accelerated by the airflow of the rotating drum into the rotating drum. Under the action of the centrifugal force field, the liquid phase in the slurry is separated by the screen set on the rotating wall, and the solid particles are intercepted. In the drum;

At the same time, the solid particles in the drum move from the small end of the drum to the big end of the drum under the action of centrifugal force and the differential speed between the spiral and the drum. During this movement, due to the diameter of the rotation Increased, the centrifugal force is rapidly increased, and the solid phase changes from the high moisture content solid phase when it initially enters to the low moisture content solid phase when it is discharged from the drum, thus realizing automatic and continuous separation of solid and liquid phases.

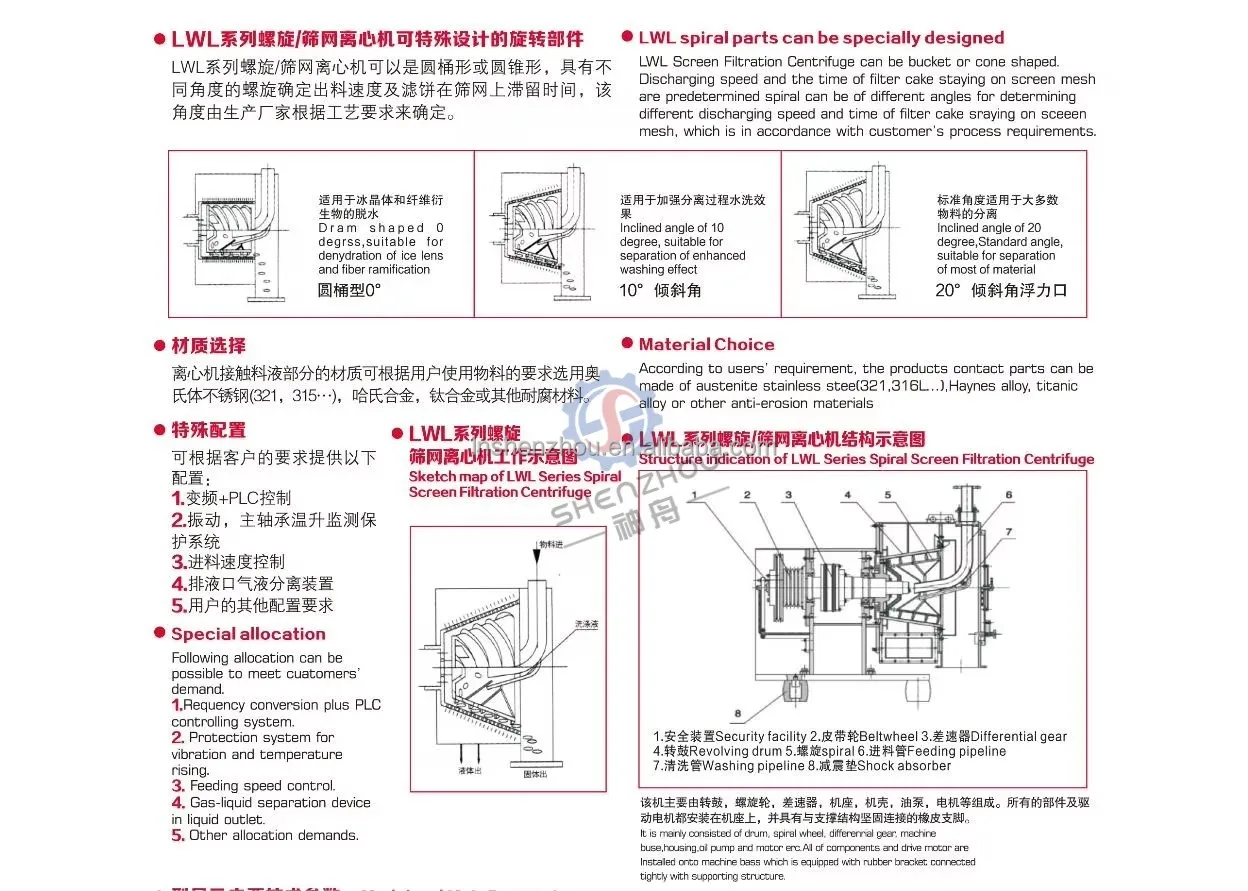

The new Y series centrifuge is an improved model based on the LWL series centrifuge. The performance of the machine is more stable, the treatment effect is better, and the service life is longer.

Like the LWL series centrifuge, it is also more specific to materials. Material analysis and corresponding tests should be carried out during the selection to determine its applicability and separation performance.