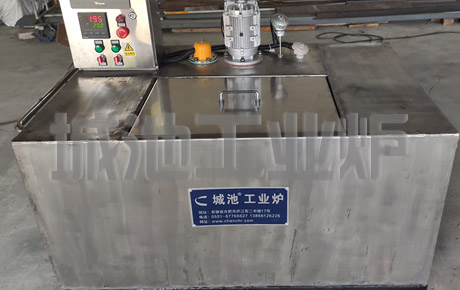

Heat treatment test quenching tank

The quenching tank in the heat treatment test is mainly used for the quenching heat treatment process in the test. The tank body is made of steel plate (heat treatment test quenching tank and inorganic solution quenching tank are generally made of stainless steel) and section steel, which are made of square, rectangular and circular tank structure. The quenching medium is heated by electric heating pipe. The quenching tank is installed with circulating pump, air-cooled heat exchanger (water cooled heat exchanger is used when the heat exchange is large), heat isolated quenching tank agitator, and automatic thermostatic temperature control cabinet. With quenching oil as quenching medium, nitrogen fire extinguishing pipeline is also required. When the quenching workpieces are heavy, the automatic lifting quenching worktable can also be selected, and even the box-type quenching tank integrated furnace can be directly selected.

The quenching tank for heat treatment test can be divided into: quenching oil tank for heat treatment test, quenching water tank for heat treatment test, quenching salt tank for heat treatment test, etc.

Work flow of quenching tank for heat treatment test: before quenching, check whether the temperature of quenching medium is appropriate (if the temperature is too low, open the heating system), and then open the agitator. When the quenching medium forms a stable flow state, start quenching. When the quenching medium temperature rises due to quenching when the quenching workpiece enters the quenching tank, the cooling circulating pump starts to work, and the high temperature quenching medium in the quenching tank is pumped into the heat exchanger. At this time, the cooling circulating water is automatically connected. Through the heat exchange of the heat exchanger, the cooled quenching medium is returned to the quenching tank, and the quenching tank is cooled by reciprocating circulation. When the quenching oil bath temperature decreases, the heating tube automatically controls the temperature and heats to keep the quenching medium constant temperature within the specified process quenching temperature range.

Chengchi Industrial Furnace focuses on producing various non-standard heat treatment test quenching tanks. The quenching tank has the functions of heating, cooling, circulation, lifting, automatic nitrogen spraying fire extinguishing, automatic temperature control, etc. while meeting the requirements of liquid loading. More importantly, in terms of the core technology of quenching tank - mixing, diversion and flow equalization system, we have used a lot of experience in the whole process of "quenching tank production - customer feedback - production improvement" to continuously update the flow of the medium in the effective quenching zone of the quenching tank, so as to effectively reduce the quenching distortion, cracking, scrap and other losses caused by the uneven quenching cooling of the workpiece, Through the evolution of equipment functions to ensure the stable realization of process, improve product quality and stability.

bio-equip.cn