Home >Products> Lab Water | Ultrafilters | Concentration | Reaction >Ultrafilters> ZYM Medical Laboratory Ultra Pure Water Purification Equipment

Lab Water | Ultrafilters | Concentration | Reaction:

Lab Water

Ultrafilters

Concentration / Rotary Evaporators

Reaction Kettle / Glass Reactor

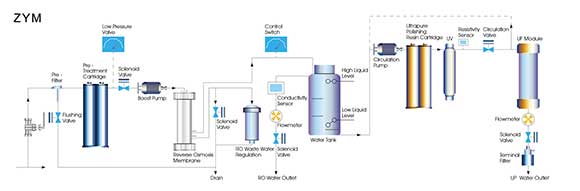

- ZYM Medical Laboratory Ultra Pure Water Purification Equipment

| Request Information |

| Related News |

| Related Products |

| Recently viewed products |