Farabead® Electrically Conductive Ni Particles

Farabead® nickel-plated particles produced by Nano-Micro have outstanding size uniformity,high conductivity, and appropriate elasticity. There is also a strong adhesion between the metal layer and the resin core of Farabead® Ni particles. As a conductive filler, Farabead® Ni particles are present in coatings, adhesives, printing ink, plastics, and rubber to provide electrical conductivity, electromagnetic shielding, and antistatic resistance in electronics, communication devices, and avionics.

Characteristics

u Monodisperse resin particles as core and metallic nickel as shell

u Broad size selection: 3.0 µm − 10.0 µm (in 0.1 µm increment)

u Uniform in size and shape, coefficient of variation (CV) ≤ 3.5%

u Good dispersivity, no overlaps or aggregates

u Suitable hardness for high conduction reliability

u Low resistance, high stability under heat and humidity

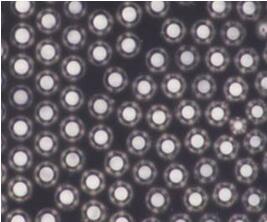

Optical and SEM micrographs of FaraBead® Ni particles

Farabead® Ni

|

Product

|

Diameter

|

Increment

|

CV

|

K at 10% deformation*

|

Metal thickness

|

Nickel content

|

|

NI

|

7.00–10.00

|

0.25

|

≤3.5%

|

~450

|

100–150

|

25–35

|

|

3.00–6.75

|

0.25

|

≤3.5%

|

~500

|

100–150

|

30–40

|

* The K value at 10% deformation is defined by the following equation:

wherein F and S represent a load value (kgf) and a compression displacement (mm) at 10% compression deformation of the particle, respectively, and R represents a radius (mm) of the particle.

bio-equip.cn