Auto-Dry Technology is a one-step method to developing a successful freeze drying run.The main objective of freeze drying equipment is to control the freeze drying process while keeping the product temperature and freeze drying interface below its critical temperature. The critical temperature can be considered the point at which the product melts back or collapses. If the product melts back or collapses its resulting in a non-elegant cake and shelf life and/or reconstitute ability may be compromised.

Historically, due to the FDA requiring consistent and repeatable drying profiles, open loop control has been used to control the product temperature throughout the freeze drying run. The concept applied was to control the shelf temperature and vacuum levels to keep the product below its critical temperature. The problem with this methodology is that the heat transfer dynamics of the freeze drying process change with time and the same shelf temperature and vacuum level will produce different product temperatures throughout the run.

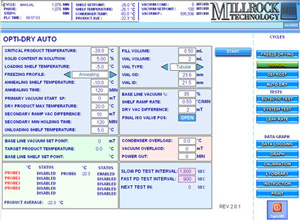

|

In vials, freeze drying progresses from the top surface of the product toward the bottom. The area where sublimation is taking place is called the sublimation interface or freeze drying front. As the product dries a dry region builds up which blocks vapor flow, changing the drying dynamics.

The highest temperature in a vial is at the bottom. The coolest temperature is at the sublimation front. A system of measurement needs to be in place to keep the highest temperature (bottom of the vial) below the critical temperature. There are many methods for monitoring or measuring product temperatures, each with their advantages and disadvantages. Some methods are specific to a vial, others measure the average for the batch. |

|

Using open loop control requires a conservative process. Since the true product temperature is not measured and the heat transfer characteristics change throughout the run, the optimum shelf temperature changes during the cycle.

Batch Control

The present state of the art method for optimizing a freeze drying run uses pressure rise data to perform calculations and ‘expert assumptions’ to estimate the shelf temperature and drying times. This method is limited in use since it provides a conservative result based on average batch parameters.

Issues with the existing MTM method for optimizing the freeze drying run:

·All measurements are batch based, when used for control the result may be a % of product that collapses or melts back or an overly conservative run is required to protect all the vials.

·Steady state heat transfer calculations are used to approximate dynamic conditions

·Many assumptions are made and not tested or measured, the result is a conservative run.

·Control is still open-loop during a major portion of primary drying (1/3 to 1/2)

Single Point Control – Critical Vial Control

The freeze drying rate across and between shelves produces higher temperatures at the corners and front of the shelf, resulting in drying from the corners toward the middle of the shelf. Shelf temperature uniformity results in temperatures higher at the fluid outlet than at the fluid inlet, and so on. Therefore, vial based measurements are required.

|

The key to critical vial control is a method to determine that the temperature sensing device used for control is the highest vial temperature where the sensor is still reading the ice temperature. Therefore, all the sensors are monitored and compared to each other to determine the highest temperature vial. Auto-Dry can determine if the sensor is still in the ice. If the sensor is no longer in ice, then it is disabled and no longer used for control purposes.

Advantages of the Critical Vial Cascade Method are:

·Prevention of melt back and collapse

·Optimized shelf temperature

·Ability to measure and control the process for a longer portion of primary drying than MTM by itself

·Wide range of batch sizes

·Eliminate assumptions and calculation errors |

|

End of Primary Drying

|

Normally the manometric temperature measurement method determines the End of Primary drying as the pressure rise of less than 5mT in 25 seconds. This will not work without a sufficient batch load.

The Critical Vial Cascade Method use any or all the following (user selectable):

·Product Temperature > Shelf Temperature

·Pirani vs Capacitance Manometer Differential

·Pressure rise < X mT in X period of time |

| When all the parameters are met, the primary drying cycle will proceed to a ‘predetermined finishing routine’ to ensure that all product is dry. The result is a high level of confidence that the product has properly completed primary drying.Auto-Dry can be retrofit to existing equipment and is also scalable to production systems. |

bio-equip.cn