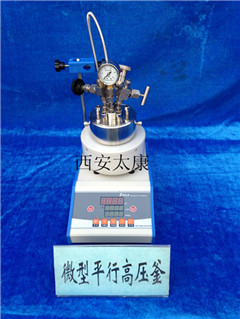

Mini magnetic high pressure reactor is mainly used in the fields of biochemical, chemical material, environmental protection new material reaction etc

Applications: catalysis, high temperature and pressure synthesis, dynamics testing, Fischer- Tropsch, and hydrogenation reaction.

Technical Parameters:

1. Material: Shell stainless steel, liner is PTFE, high quality pure titanium or hastelloy alloy

2. Heating: Heating plate to heat directly, a suitable temperature sensor fitted to measure internal temperature, temperature control accurate, simple and convenient to operate

3. Pressure gauge, digital pressure indicator in Mpa, pressure safety valve will release gas from vent valve when pressure is higher than safety pressure

4. Valve pipe fittings are original German imports with standard connectors.

5. Digital display stir speed and temperature on the heating plate

6. Use patented plug-in stylus K-sensor, standard mixing devices, titanium reactor body, and electric fiber furnace; insert the K-type sensors.

7. Insert temperature, pressure, PH value, conductivity sensors, to ensure accurate measurement of relevant data.

|

Model

|

TCGF

-25ML

|

TCGF

-50ML

|

TCGF

-100ML

|

TCGF

-200ML

|

TCGF

-300ML

|

TCGF

-400ML

|

TCGF

-500ML

|

TCGF

-1000ML

|

|

Capacity

|

25ml

|

50 ml

|

100 ml

|

200ml

|

300ml

|

400ml

|

500ml

|

1000ml

|

|

Safety pressure

|

10Mpa

|

|

Safety temperature

|

280℃(Shell stainless steel, liner is PTFE)

380℃(high quality pure titanium or hastelloy alloy)

|

|

Stir speed

|

0-1500Rpm

|

|

Speed accuracy

|

±1 Rpm

|

|

Heating power

|

300W-500W

|

|

Temperature accuracy

|

±1°C.

|

|

Temperature sensor

|

Yes

|

|

Pressure gauge

|

Yes

|

|

Vent valve

|

Yes

|

|

Heating plate

|

Yes

|

|

Visual type

|

optional

|

|

Computer control system

|

optional

|

bio-equip.cn