Home >Products> Centrifuges >Other Centrifuges> Gq105 Chlorella Microalgae Tubular Centrifuge Separator

Centrifuges :

High-speed Refrigerated Centrifuges

Large-capacity Centrifuges

Benchtop Centrifuges

Other Centrifuges

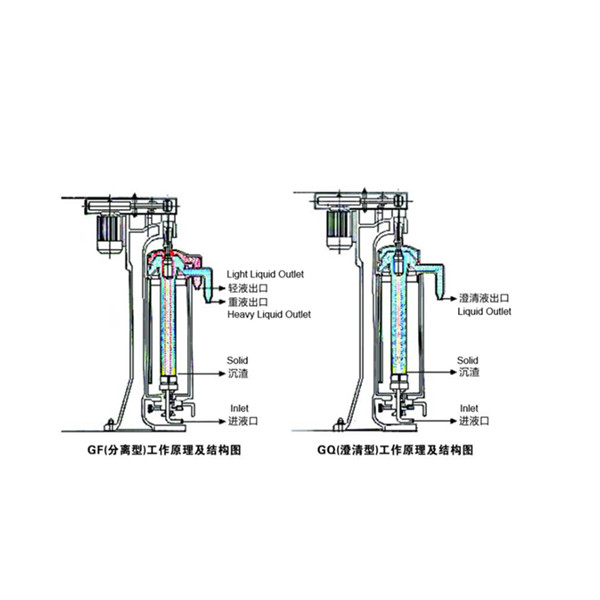

- Gq105 Chlorella Microalgae Tubular Centrifuge Separator

| Request Information |

| Other Products |

| Related Products |