High Throughput Automated Micro Bioreactor for Predictive Cell Line and Media Screening

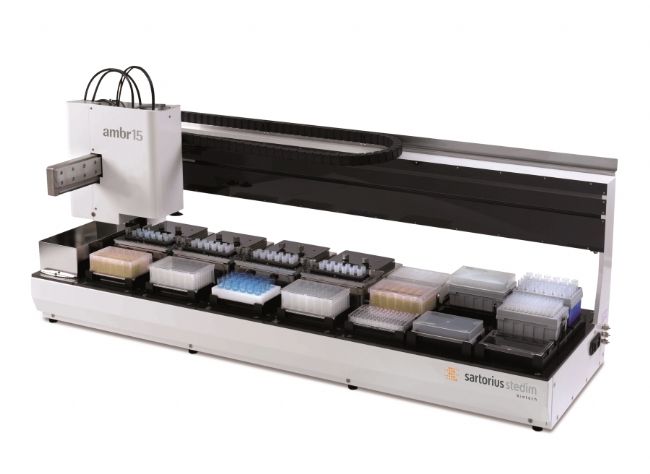

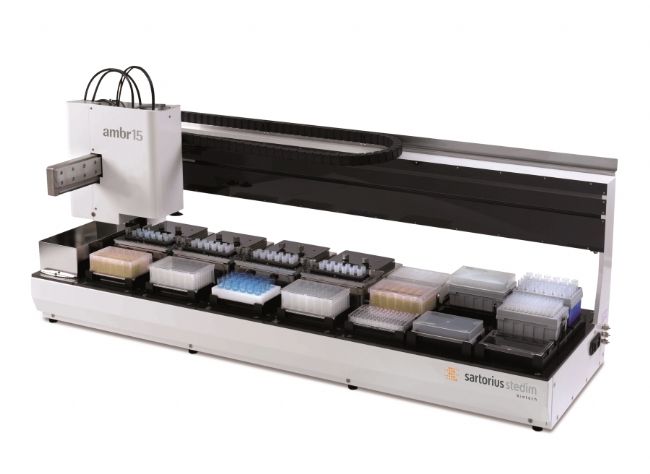

ambr® 15 cell culture is a high throughput, automated bioreactor system for 24 or 48 parallel cultivations in a cost-effective 10 –15 mL micro bioreactor format.

It has a wide range of applications in:

Cell line selection

Media and feed screening

Media development

Early process optimization

Small-scale perfusion mimic

QbD and DoE studies

The ambr® 15 cell culture system enables the rapid evaluation of multiple bioreactor cultures at microscale, increasing productivity in cell line development with significant savings on materials and labour.

ambr® 15 has been proven by industry leaders to provide better scalability than a shake flask and has transformed cell line development in many leading biopharma companies worldwide.

The ambr® cell culture workstation features:

Parallel processing and evaluation of multiple experiments

Closed loop control of pH and DO

Independent gassing for each bioreactor of O2, CO2 and N2

Culture station control of impeller speed and bioreactor temperature

Automated addition of feeds and other reagents

Fully integrated Nova BioProfile Flex2 for automated sampling and Feedback control

ambr® 15 transforms cell line development

Improves early clone selection decisions

Is the established industry standard

Helps create better cell lines faster

Simplifies adoption of Quality by Design (QbD) principles

Increases lab productivity

Reduces the cost per experiment

ambr® 15 cell culture Tour

Micro bioreactor vessel

The core disposable micro bioreactor technology includes sensors, stirring impeller, gas sparging and sample port.

The image shows the standard vessel, however several variations are available.

bio-equip.cn